The list of elements to be controlled variates according to local needs but can be summarized in:

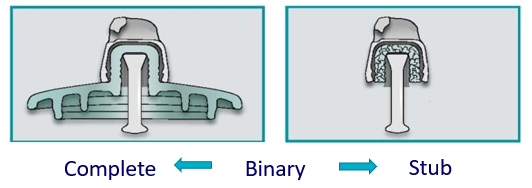

a. Checking the presence of stubs in the strings.

b. Checking the presence of pollution at the surface of the insulator.

c. Checking the corrosion of metallic parts.

The first inspection’s step can be fulfilling from the ground with no need of instruments, with an enhanced worker’s safety in live line operations and for a very low cost of inspection for the entire service life of the line.

TGI – A binary behavior

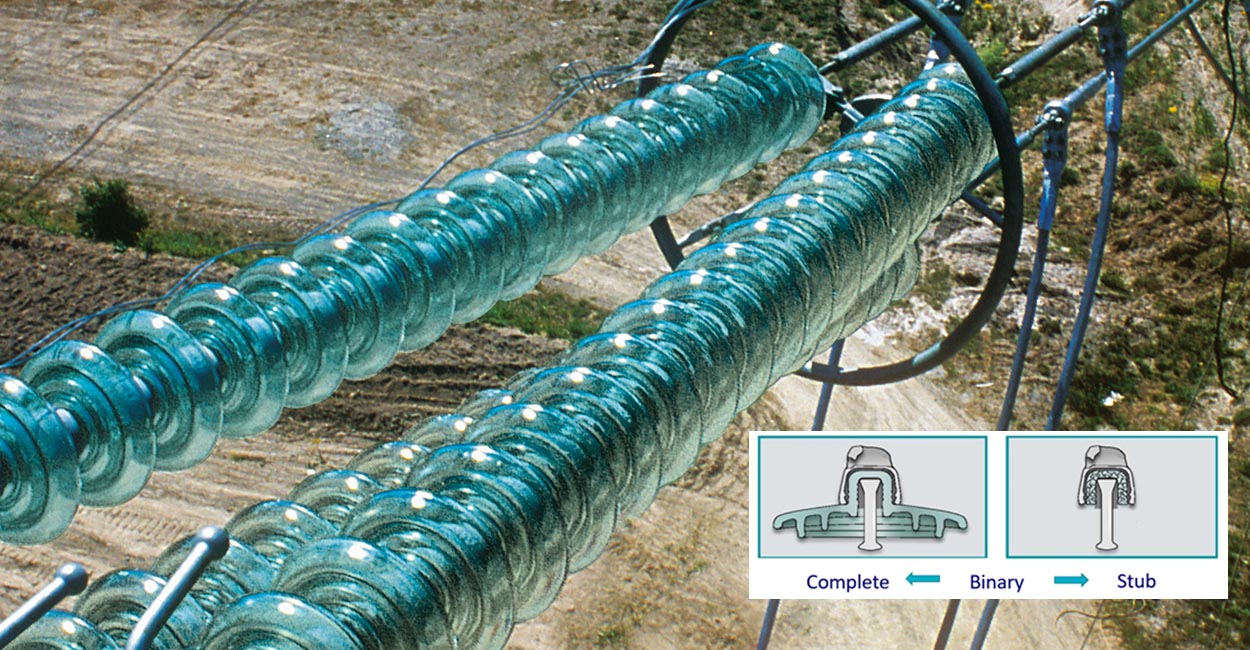

Sediver® Toughened Glass insulators can only exist in two well defined conditions: intact or shattered. It shows a binary status with no intermediate cracked or punctured state.

Therefore, it is easy to quickly and infallibly inspect strings of toughened glass, with no need for instruments other than the naked eye. No need for highly qualified and costly training to learn how to inspect.

Infallible, easy visual inspection

On the following video, please look for the broken piece

A fail-safe inspection

- No risk of wrong interpretation: you get what you see

- Safe live-line working

At a glance visual inspection

- No need for any testing instrument

- No need for climbing the tower: inspection from the ground.

- No risk of hidden defect

- Easiest maintenance procedure

No need for immediate maintenance

- No risk of line drop

- Residual mechanical strength: 80% of the mechanical rating, guaranteed over prolonged periods of time even with in-service dynamic loads and temperature cycling. The broken piece doesn’t represent a weak point in the string

- Residual electrical strength: Avoiding internal puncture and forcing overvoltage induced discharges externally.

Discover our complete range of Toughened Glass insulators

The information collected through this form are processed by SEDIVER, a simplified joint stock company, registered with the Nanterre Trade and Company register under number 542035761 and whose headquarter is located 7/9 allée de l’Arche 92400 Courbevoie for the purpose of allowing the download of our whitepaper documents and to send you information about our group’s companies and products. The legal basis for these processing activities is our legitimate interest to know who access and download our resources and to send them direct communication.

Fields marked with an asterisk (*) are required information. Should you fail to give this required information, you will not be able to download our whitepaper documents.

You have a right of access, rectification, erasure and limitation with regard to the processing of your personal data as well as the right to define guidelines regarding what happens to your data after your death and the right of portability of your personal data, to the extent applicable under local legislation. You also have a right to object to the receipt of marketing communication by ticking the dedicated box of this form, and at any time by clicking on the unsubscribe link placed in all our marketing communications.

To find out more about how we process your personal data and to exercise your rights, please refer to the SEVES group EU privacy policy and the SEDIVER privacy policy.

For more information, please consult our Privacy Policy.

English

English