We are continuing our journey through the pollution and how does it impact the performance of T&D overhead lines.

First you need to understand what is pollution and how characterized it by reading our Pollution Starter Kit.

What is pollution?

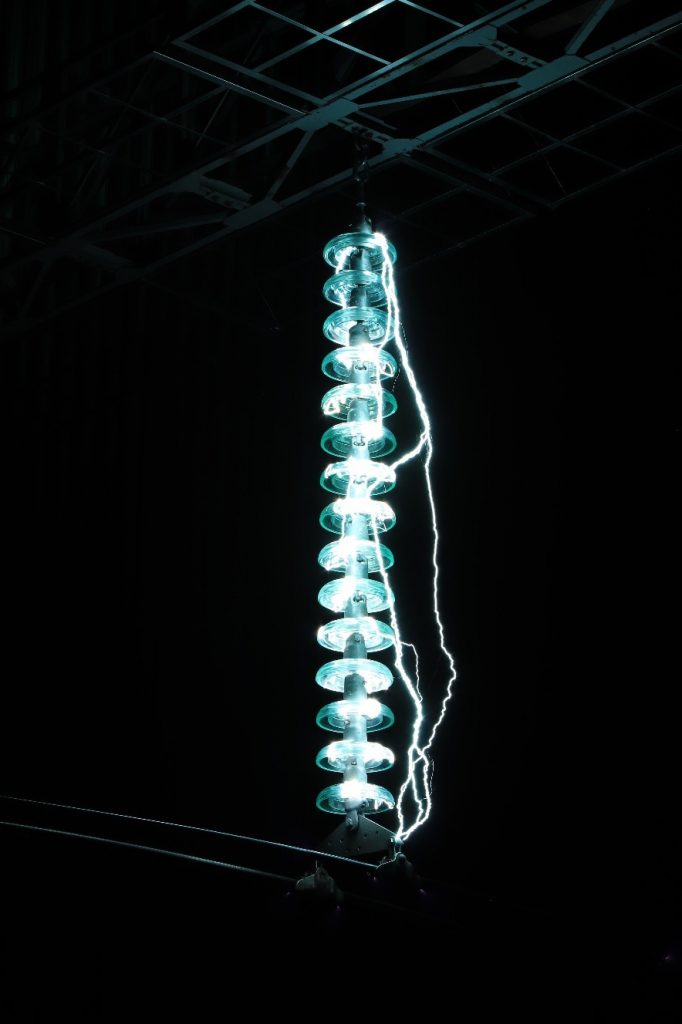

After many years of operations a series of elements can be deposited over the surface of the insulator. All these elements can have an impact on the performance of the string and may lead to a flashover…

How flashover occurs in polluted environment?

In contaminated conditions, contaminants deposit on the insulator surface can lead to the formation of a conductive layer, resulting in a flow of leakage current, dry band formation and, under certain conditions, flashovers.

- Pollution is deposited on the insulator surface

- Solid layer (A) is wetted by rain, dew, fog etc..

- Surface leakage current in the pollution forms dry bands.

- Localised drying causes partial flashover of dry bands

- If the resistance of the remaining layer is low enough, arcs can extend along the insulator

- Flashover

How avoids any flashover?

Several solutions can be used to avoid any flashover in polluted environment.

The first one is to wash regularly the insulators, but this solution is expensive and not safe for the linemen.

Another solution is to use RTV coating over glass insulators.

How Sedicoat insulator RTV silicone coated glass limits flashover appearance?

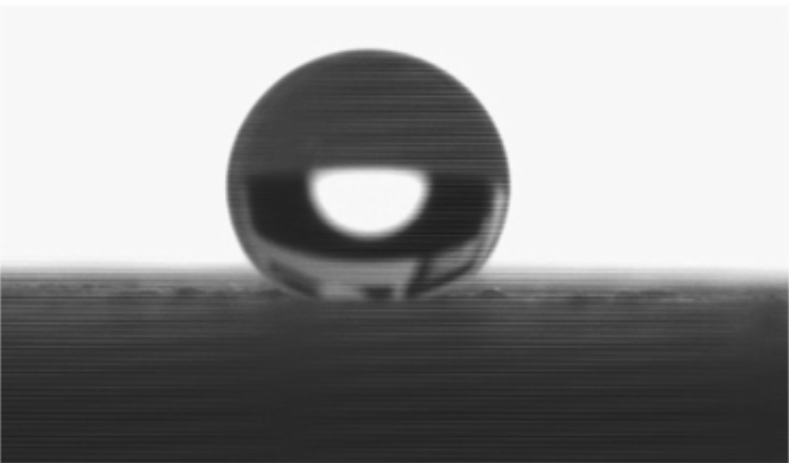

The water repellent property of the RTV coating keeps the water droplets apart on the surface of the insulator: no formation of conductive water film on the surface.

Leakage currents are reduced on the surface of the insulator:

- No dry band

- No flashover

But what is the point of coated glass?

Sedicoat insulator = Toughened Glass Insulator with a coating

You will keep the unique property of TGI under its silicone layer: Binary status due to the toughening process, with no hidden puncture or crack.

the only material which allows a complete, reliable “at a glance” inspection from a distance. Safest maintenance with no need for any instruments or emergency maintenance.

Benefits of glass insulators with silicone coating

Specific properties of Silicone

- Eliminates the need for insulators to be washed regularly

- Eliminates the risk of flashover due to pollution

Inherent properties of toughened glass

- Infallible visual inspection

- Safe live-line working

- Long-term reliability

Do not require any line design modification

To discover more about Sedicoat, please see our product section.

The information collected through this form are processed by SEDIVER, a simplified joint stock company, registered with the Nanterre Trade and Company register under number 542035761 and whose headquarter is located 7/9 allée de l’Arche 92400 Courbevoie for the purpose of allowing the download of our whitepaper documents and to send you information about our group’s companies and products. The legal basis for these processing activities is our legitimate interest to know who access and download our resources and to send them direct communication.

Fields marked with an asterisk (*) are required information. Should you fail to give this required information, you will not be able to download our whitepaper documents.

You have a right of access, rectification, erasure and limitation with regard to the processing of your personal data as well as the right to define guidelines regarding what happens to your data after your death and the right of portability of your personal data, to the extent applicable under local legislation. You also have a right to object to the receipt of marketing communication by ticking the dedicated box of this form, and at any time by clicking on the unsubscribe link placed in all our marketing communications.

To find out more about how we process your personal data and to exercise your rights, please refer to the SEVES group EU privacy policy and the SEDIVER privacy policy.

For more information, please consult our Privacy Policy.

English

English