This content is based on the article “POLLUTION MITIGATION SOLUTIONS FOR OVERHEAD LINE INSULATORS” by J.M. GEORGE, D. LEPLEY, E. BROCARD, F. VIRLOGEUX, S. ROUDE

The global term « pollution » is very often assimilated to anything that comes on the surface of an insulator and affects the insulating properties. But such « pollution » should be defined precisely to allow for the most appropriate counter measure selection.

In contaminated conditions, contaminants deposit on the insulator surface can lead to the formation of a conductive layer, resulting in a flow of leakage current, dry band formation and, under certain conditions, flashovers.

The challenge for line design engineers and maintenance crews is to know how such electric flashovers can be avoided by either using insulators catching less contaminants, more resistant to arcing or designed and made with materials which will reduce the ability of an external arc to take place.

When dealing with pollution problems experts use several definitions:

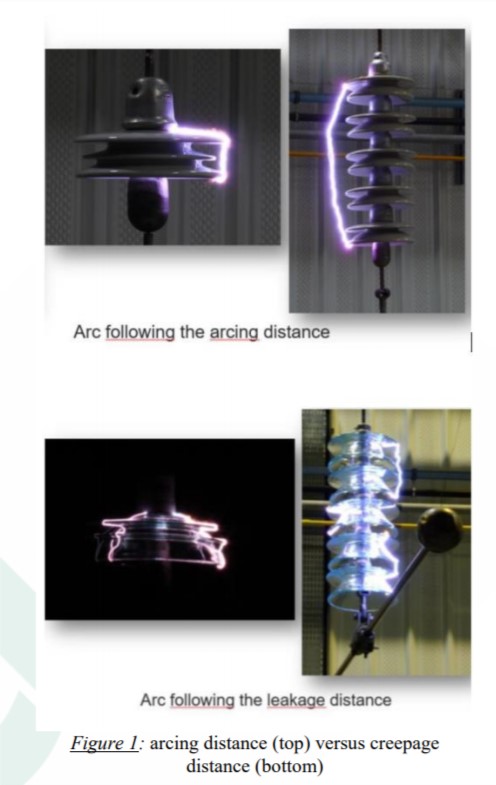

Creepage distance: (sometimes the word “leakage distance” is being used). It is the distance an arc needs to cover from one metal end fitting to the next one following the surface of an insulator (figure 1).

Arcing distance: the shortest distance between ground and energized side of an insulator (figure 1)

ESDD is the acronym for Equivalent Salt Deposit Density. It represents the quantity of salt required to achieve the conductivity reached by the pollutant dissolved in the water.

When salts dissolve in water the conductivity of the humid/wet film on the surface of the insulator increases, and subsequently the risk of having a flashover increases as well. The unit of measure is mg/cm².

NSDD is the acronym for Non-Soluble Deposit Density. It corresponds to the amount of deposit on the surface of the insulator which does not dissolve in water and remains inert on the surface. Sand for example is a typical component of NSDD. The non-soluble component of the pollution layer will work like a sponge catching more humidity which in turn will facilitate the conductivity on the surface of the insulator.

Leakage current: is the electric current flowing along the surface of an insulator along the leakage distance. Each insulator type has a limit above which the leakage current will lead to arcing and possibly a complete bypass of the insulator (this final stage of arcing is then called flashover).

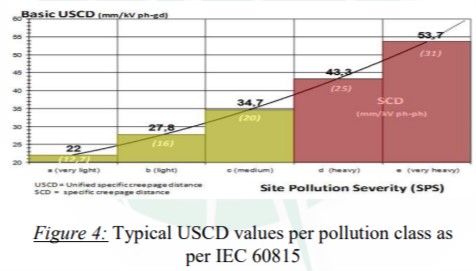

Specific leakage distance: the ratio between the leakage distance of an insulator (or string of insulators) and the phase to ground voltage. The unit is mm/ kV and referred to as USCD (Unified Specific Creepage Distance)

Dry band arcing: is a dynamic process by which an arc once initiated will dry the area where it takes place. By drying a segment of the insulator, the arc will progressively have more and more difficulties to be sustained, will self-extinguish until the surface is wet again, leading to currents which will generate new arcs, new dry spots….

The evaluation of the pollution level

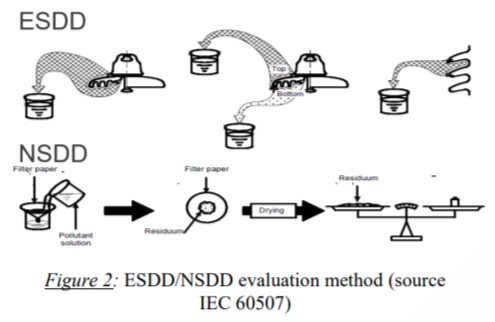

The evaluation of the pollution level in any given area on an insulator can be made by measuring both ESDD and NSDD.

The procedure consists in washing the surface of the insulator with deionized water which conductivity is measured prior to washing.

After washing, the conductivity is measured again, and tabulated for conversion in equivalent salt weight. This number is then divided by the surface which was washed (ESDD value). Once this is done, the washing water is filtered on a paper filter which needs to be dried in an oven.

The weight of solid deposit is divided by the surface of the insulator to give the final NSDD in mg/cm². (figure 2)

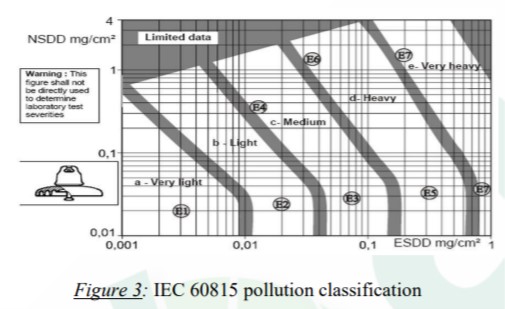

Once ESDD and NSDD are defined, it is possible to establish the pollution class as per IEC 60815 (figure 3).

For each class of pollution IEC gives an average USCD as a reference base value for selecting a leakage distance in the environment under consideration (figure 4).

With this evaluation, expert can choose the better insulators solution to deal with this pollution environment, and even go further with a live leakage current measurement to follow the development of surface currents and be in position to anticipate any critical situation.

To discover more about our insulators solution for polluted environment see our Sedicoat® insulator, a toughened glass insulator factory-processed with an RTV silicone coating which eliminates the need for regular washing, our or live leakage current measurement solution Sediver Smart’R Suite

The information collected through this form are processed by SEDIVER, a simplified joint stock company, registered with the Nanterre Trade and Company register under number 542035761 and whose headquarter is located 7/9 allée de l’Arche 92400 Courbevoie for the purpose of allowing the download of our whitepaper documents and to send you information about our group’s companies and products. The legal basis for these processing activities is our legitimate interest to know who access and download our resources and to send them direct communication.

Fields marked with an asterisk (*) are required information. Should you fail to give this required information, you will not be able to download our whitepaper documents.

You have a right of access, rectification, erasure and limitation with regard to the processing of your personal data as well as the right to define guidelines regarding what happens to your data after your death and the right of portability of your personal data, to the extent applicable under local legislation. You also have a right to object to the receipt of marketing communication by ticking the dedicated box of this form, and at any time by clicking on the unsubscribe link placed in all our marketing communications.

To find out more about how we process your personal data and to exercise your rights, please refer to the SEVES group EU privacy policy and the SEDIVER privacy policy.

For more information, please consult our Privacy Policy.

English

English