We are finishing our journey through our insulator RTV silicone coated glass story by presenting the under coating alternative.

Our technical assistance team is available to help you to choose the best solution for your application.

In the meantime, to clearly understand the difference between the two technologies we are presenting the under coating option and its benefits in this article.

Benefits of glass insulators with silicone under coating

Silicone coated toughened glass insulators

- Hydrophobicity assured in the protected creepage distance

- No washing – No flashover due to pollution

- Glass insulators long-term reliability

Additional characteristics of under coating

- Insulator strings less sensitive to damage during installation

- Handling like regular glass units

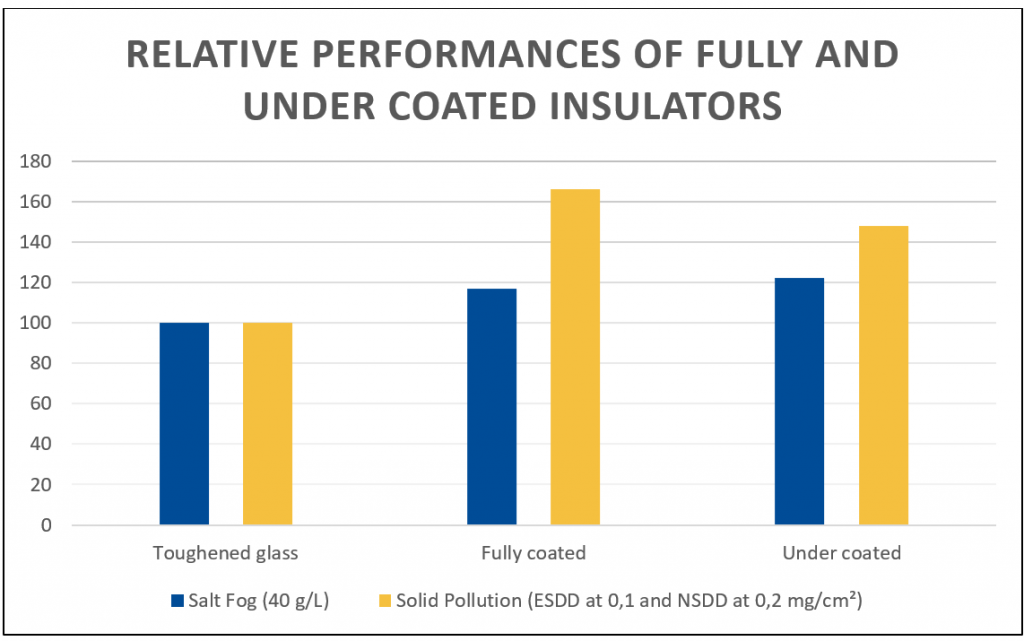

- Pollution flashover voltage higher than naked glass insulators and similar to fully coated insulators

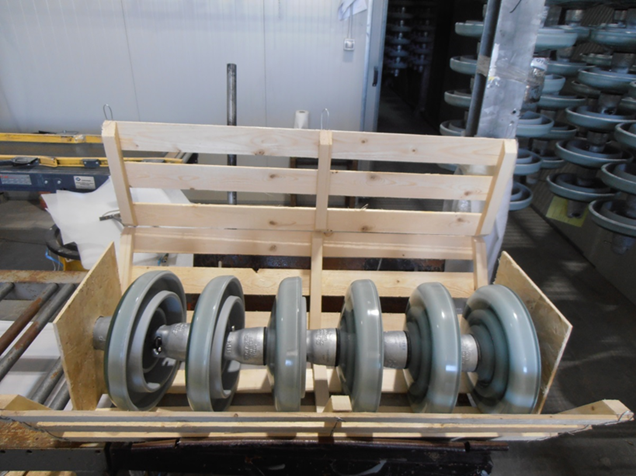

- Same packaging as regular glass insulators

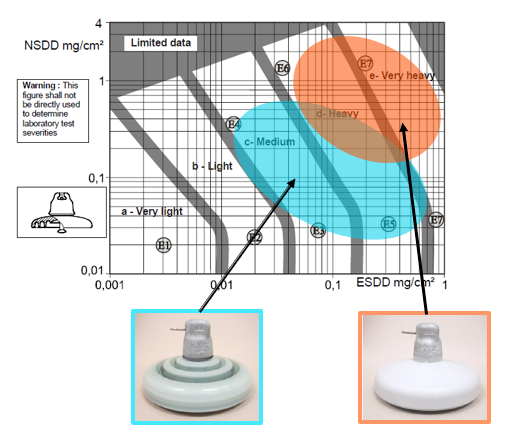

When to use Fully coated vs under coated units?

Insulator strings in very heavy (IEC) pollution classes will generally require fully coated insulators, while under coated insulators are suitable for Medium and Heavy pollution areas (IEC)

Under coating, for most cases, offers an optimized solution since it ensures a performance close to a fully coated insulator, with the benefit of packing and handling conditions similar to non-coated insulators.

Under Coated insulators: benefits in packaging and handling

Similar packaging as naked glass insulators

Want to know more about insulator RTV silicone coated glass?

To complete your understanding of factory insulator RTV silicone coated glass, please look at the other articles of this series:

The information collected through this form are processed by SEDIVER, a simplified joint stock company, registered with the Nanterre Trade and Company register under number 542035761 and whose headquarter is located 7/9 allée de l’Arche 92400 Courbevoie for the purpose of allowing the download of our whitepaper documents and to send you information about our group’s companies and products. The legal basis for these processing activities is our legitimate interest to know who access and download our resources and to send them direct communication.

Fields marked with an asterisk (*) are required information. Should you fail to give this required information, you will not be able to download our whitepaper documents.

You have a right of access, rectification, erasure and limitation with regard to the processing of your personal data as well as the right to define guidelines regarding what happens to your data after your death and the right of portability of your personal data, to the extent applicable under local legislation. You also have a right to object to the receipt of marketing communication by ticking the dedicated box of this form, and at any time by clicking on the unsubscribe link placed in all our marketing communications.

To find out more about how we process your personal data and to exercise your rights, please refer to the SEVES group EU privacy policy and the SEDIVER privacy policy.

For more information, please consult our Privacy Policy.

English

English